Air brake systems play a crucial role in ensuring the safety and performance of commercial vehicles. Within these systems, pneumatic valves are vital components that help regulate air pressure and control various functions.

Proper troubleshooting, maintenance, and upkeep of these valves are essential to ensure optimal functionality and driver safety.

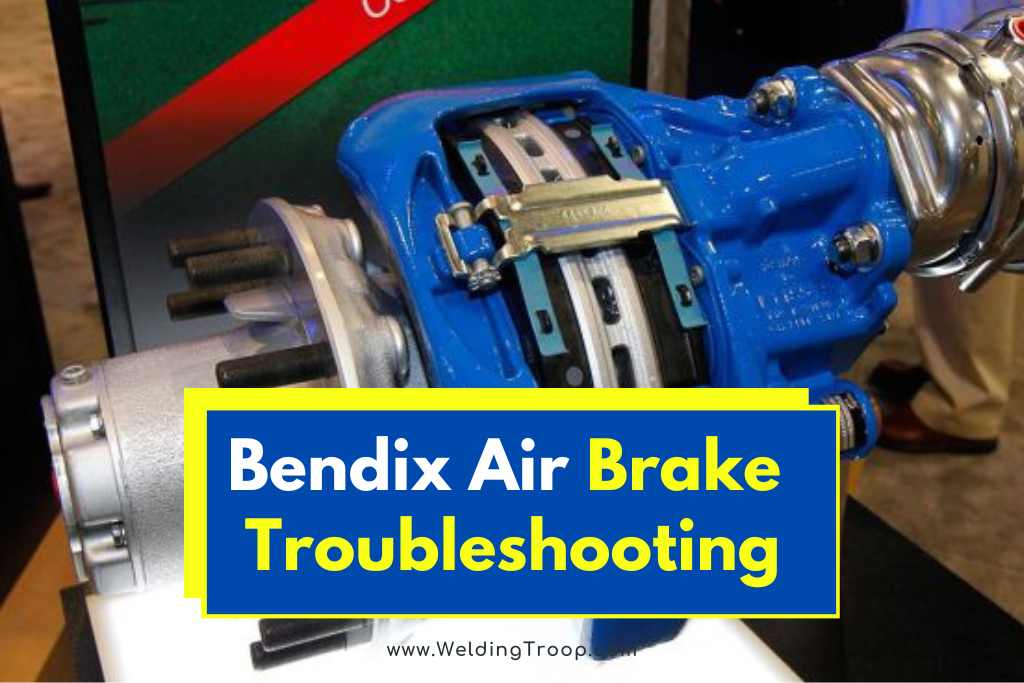

In this comprehensive guide, we will explore the common issues related to Bendix air brake valves, discuss troubleshooting techniques, and provide insights into valve replacement and maintenance.

Table of Contents

Understanding Bendix Air Brake Valves

A typical commercial vehicle air braking system consists of multiple pneumatic valves designed to meet regulatory standards and cater to customized requirements.

These valves can range from basic components to mechatronic ones with solenoids used in antilock braking and stability control systems. Automated manual transmissions, emissions controls, and other systems also rely on pneumatic controls.

Valves within the air brake system are responsible for various functions, such as controlling air pressure, regulating brake applications, and ensuring proper operation of auxiliary systems like lift axles.

With the complexity and interconnectedness of these valves, it’s crucial to recognize and diagnose any issues that may arise.

Common Valve Problems and Symptoms

One of the most common concerns with air brake valves is leakage, often noticeable through an audible air hiss. To identify leaks, a bubble solution applied to suspected areas can help pinpoint the severity and location of the issue.

Additionally, some valves, such as dash valves, have trip pressures or pop pressures that can be easily detected if incorrect. Loose pedals or abnormal travel distances can also indicate underlying valve problems.

However, it’s important to approach valve troubleshooting from a system-level perspective. By observing the vehicle’s behavior and referring to service data sheets, guides, and checklists, technicians can narrow down the potential locations of faulty valves within the system.

Troubleshooting Techniques

When troubleshooting Bendix air brake valves, it’s crucial to follow a systematic approach to identify and resolve issues effectively. Here are some techniques to consider:

1. Visual Inspection

Perform a visual inspection of the valves, connecting hoses, and fittings to check for any visible damage, corrosion, or loose connections. Ensure that all components are securely fastened and aligned correctly.

2. Functional Testing

Conduct functional tests to assess the performance of the valves. This may involve checking trip pressures, override functions, and other operations specific to each valve type. Consult manufacturer guidelines for recommended testing procedures.

3. Diagnostic Tools

Utilize diagnostic tools, such as handheld scanners or computer-based systems, to gather diagnostic trouble codes (DTCs) and identify any electrical or sensor-related issues. These tools can provide valuable insights into the root cause of valve malfunctions.

4. System Pressure Checks

Measure the air pressure within the system using appropriate gauges to ensure it falls within the recommended range. Deviations from the specified pressure may indicate problems with the valves or other components.

5. Air Flow Analysis

Analyze the air flow within the system to identify restrictions or blockages that could affect valve performance. This can be done by assessing pressure differentials and monitoring air flow rates at various points.

Read also >> Brake Controller Troubleshooting (Here Is What To Do)

Read also >> Brake Booster Troubleshooting (Diagnose and Fix)

Valve Replacement and Maintenance

If troubleshooting efforts indicate the need for valve replacement, it’s essential to follow proper maintenance procedures to ensure a successful installation and optimal performance. Here are some key considerations:

1. Safety Precautions

Before starting any maintenance work, adhere to general safety guidelines provided by the manufacturer. This includes chocking the wheels, draining the air system, and wearing appropriate personal protective equipment (PPE) to prevent injuries.

2. Dressing the Valve

When handling a new valve, dress it with fittings before installing it on the vehicle. If the valve has an integrated mounting surface, utilize it to hold the valve securely during the dressing process.

Avoid squeezing or altering the shape of the valve, as even slight changes can lead to further complications.

3. Thread Sealant Usage

Apply an adequate amount of thread sealant to the fittings, ensuring a proper seal without excessive use. Excess sealant can enter the valve and impede its internal movement, potentially causing malfunction.

4. Torque Application

When tightening fittings, always follow the recommended torque specifications provided by the manufacturer. Avoid backing off the torque once applied, as this can compromise the integrity of the connection.

5. Correct Valve Orientation

Ensure the correct orientation of the valve during installation. The exhaust port should always face downward to prevent the accumulation of water or contaminants within the valve.

Conclusion

Proper troubleshooting and maintenance of Bendix air brake valves are crucial for ensuring the safety and performance of commercial vehicles.

By following systematic approaches, conducting thorough inspections, and utilizing diagnostic tools, technicians can identify and resolve valve issues effectively. When replacing valves, adherence to safety precautions and proper installation techniques is essential.

By prioritizing valve maintenance, commercial vehicle operators can optimize their air brake systems and promote driver safety on the road.