When you come across a brazed joint, have you ever wondered if you can weld over it? Welding and brazing are entirely different processes that use different temperatures to join metals.

Can you weld over a braze? You cannot weld over a braze unless you completely remove the brazed filler material before you weld. Brazing filler metals, such as copper, have a low melting point and will melt or crack from a high-temperature welding electrode.

Manufacturers, hobbyists, and welders use varying techniques to join metal. Sometimes, a decision to use brazing over welding results from choosing an inexpensive method over a costly one. Filler metal for brazing is cheaper than MIG or TIG electrodes. Therefore, many large-scale manufacturers prefer brazing over welding when they’re responsible for filling massive orders.

Sheet metal joining is often accomplished with brazing. However, welding produces a stronger weld on sheet metal but is more expensive. It’s important to understand the differences between brazing and welding and examine which method is more effective on certain projects.

Table of Contents

Why Shouldn’t You Weld Over a Braze?

Brazing and welding are essential techniques for joining and mending metals. Although they accomplish a similar result, brazing and welding use different methods and cannot be used interchangeably on every project. The following lists display why you shouldn’t weld over a braze.

- Filler metals for brazing have low melting points

- The base metal may have a melting point too low for welding

- Weld pools will become contaminated by the brazing

- Welding over a braze produces a weak weld

Low Melting Points

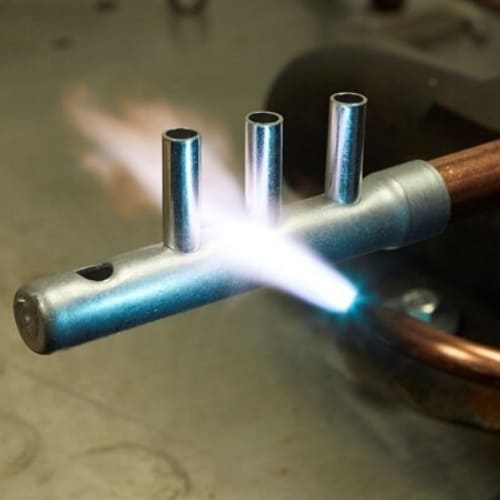

When you braze two metals together, you heat the base metals with a torch and touch a filler metal like copper or bronze to the heated base metals. The filler metal instantly melts and fills the gap between the base metals.

The brazing filler metals will always have a lower melting point than the base metals.

The braze produces a strong bond between the metals, but if it’s heated with a welding gun or torch, it will melt, crack, and sometimes pop out. Molten bronze or copper is not a good thing to have flying in your direction.

Arc Welding typically operates at temperatures between 10,000° F and 15,000° F and will easily melt and disrupt a brazed mend. MIG and TIG welders operate at temperature up to 2500° F.

Although inert gas welders use lower temperatures than stick welding, they operate at temperatures up to 1000° F higher than the melting points of most filler metals.

Base Metals with Low Melting Points

Brazing uses lower temperatures (up to 1500° F) to join metals, and it does not fuse the base metals like welding. Brazing is preferred over welding when you have two base metals with low melting points.

Since welding uses exceptionally high temperatures, it can melt or warp metals with low melting points. If you attempt to weld over a braze, you risk damaging the base metals.

Contaminated Weld Pools

Welding over a braze can lead to a contaminated weld pool. Sometimes, two different types of metals are joined by brazing. Unlike welding, brazing can join different metals without the need for changing out equipment like inert gas tanks.

Welding electrodes and inert gases must be changed when you weld different metals. If you try to weld over a braze joining two separate metals, your weld puddle can become contaminated. The contamination can lead to porosity and an inconsistent weld.

Weak Welds

If you weld over a braze, your weld is unlikely to last long. A braze is like a chemical obstacle in the way of the welding gun, and a welder will find it challenging to produce an even, sturdy weld over the brazing filler metal.

The heat of the welding gun’s arc will melt the braze, but some of the filler metal will remain. A braze is usually copper or bronze, and if it joins steel or aluminum, the welder cannot compensate for the different metals. The resulting weld will not produce a strong bond and likely will not pass inspection.

What are the Alternatives to Welding Over a Braze?

As a welder, you may encounter a project that involves mending someone’s failed attempt to weld or braze. If you no other choice but to weld over a brazed joint, you have a few options.

Remove the Braze

Welding a braze is not a problem if you completely remove the braze. You can accomplish this by cutting the filler metal and separating the two base metals. Use a grinder to remove excess braze and wipe down the metals to ensure that filler metal flakes do not remain.

After you’re sure all the filler metal is gone, you can weld the base metals. If you’re unable to cut out the braze, you can use a file or a grinder to remove the filler metal.

Use Brazing Instead of Welding

If you have a brazing setup with filler rods, you can use it to mend the old braze. You can determine which filler metal to use by examining the color of the braze. Copper braze is close to the color of copper metal, and bronze braze has a dark yellow (bronze) color.

Learn More About – Here, you can find an article from our website: What’s the Difference Between Soldering Brazing and Welding? | When To Use?

When you braze over an old joint or channel, you will not melt or disrupt the remaining braze. The old braze will soften and become more viscous, but it will not melt, crack, or pop.

Start From Scratch

You may decide that dealing with an old brazed joint is too much trouble. Welding generally produces the strongest type of bond between metals, and if it’s feasible, scrap the old metal with the braze and weld two new pieces together.

Can You Braze With a TIG Welder?

Yes, brazing can be done using a TIG welder. In this process, a filler metal is melted using the TIG welding torch to join two base metals.

Unlike welding, brazing does not melt the base metals being joined, but rather uses the filler metal to create a bond between them. TIG brazing is commonly used in the automotive industry for repairing exhaust systems and other components.

It can also be used in other applications where a strong, leak-proof joint is required.

When Should You Braze Instead of Weld?

Welding produces a strong bond between metals, but in certain situations, brazing is more effective.

- Delicate projects

- Cosmetic work

- Repetitious work

- Joining different metals

Delicate projects

When you have to maintain a low temperature near sensitive components like electronic parts, brazing is the ideal method. Brazing is unlikely to warp or disrupt the structural integrity of base metals and is more suitable for smaller, delicate projects.

Cosmetic Work

One advantage brazing has over welding is the appearance of the braze. When you braze two metals, the result is an attractive, uniform bead. In contrast, welding produces an uneven (albeit strong) bead. When the joined metal’s appearance is important, use brazing rather than welding.

When you braze two pieces together, you will not have to spend extra time cleaning the bead. Unlike welding, brazing does not require metal brushes to clean the bead.

If you would like to watch a video that shows the difference between a weld and a braze, check it out below

Repetitious Work

Large volume manufacturers rely on brazing for projects that involve simple, repetitious tasks. For instance, sheet metal producers use brazing to join metals. Brazing is faster than welding because it’s aided by capillary action.

When you touch a filler metal to two base metals, the filler metal’s molten bead is drawn forward. This action keeps the bead centered and results in a uniform joint.

Joining Different Metals

If you have to join a piece of steel to a piece of copper, brazing is the fastest and safest option. You can use one filler to join the metals, and you will not have to worry about shielding gas.

Although brazing filler metals contain flux, you should always ensure that the base metals are clean and free of coating or film. Coated or dirty metal can disrupt the braze and result in a weak bond.

Closing Remarks

Brazing and welding are essential for joining metals, but each method has its advantages in certain situations. Welding produces the strongest bond, but brazing is more suitable for low temperature, delicate, and cosmetic work. So, if you have to weld on old, brazed joint, remove the braze and fire up your welder.

Recommended Reading

What’s the Difference Between Soldering Brazing and Welding? | When To Use?