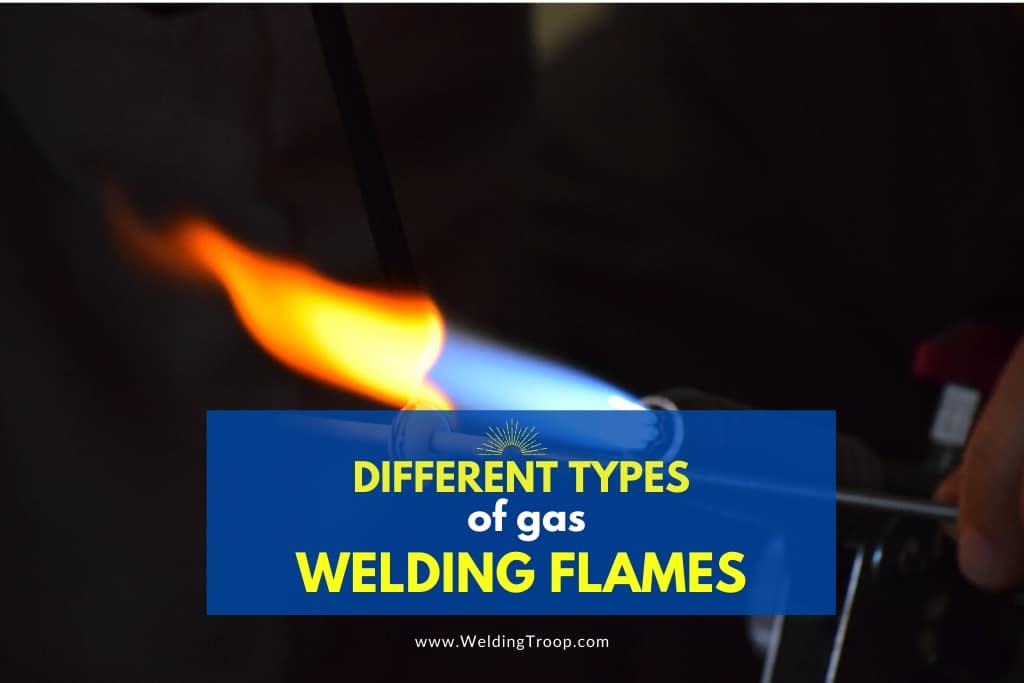

Before I learned about gas welding techniques, I assumed that the torch simply produced a hot flame to weld parts together. While the torch does produce a hot flame, there are three main types of flame. I also quickly found out that each type has distinct advantages, disadvantages, and intended uses.

So what are the types of gas welding flame? The three basic flames used for gas welding include neutral, carburizing, and oxidizing. The neutral flame burns cleanly and is used for most welding applications. Carbonizing flames are cooler and often used when working with steel or iron. Oxidizing flames are the hottest and least used, due to the oxidation of the base material.

Using the right type of flame can impact the quality of your welding job. If you want seamless welds with minimal soot or oxidation, I recommend learning more about the characteristics of each flame. Here’s a closer look at the types of gas welding flames.

Table of Contents

What Is a Flame in Gas Welding?

To learn more about the flames, I explored the basics of how gas welding works. This welding technique requires the use of a torch, which produces a flame. The flame is used to heat metal or thermoplastics, fusing them as they cool.

Most gas welding processes use oxyfuel welding. It’s one of the oldest welding processes, first developed in 1903.

With oxyfuel welding, which is also called oxyacetylene welding, you need a liquid fuel or gas, such as acetylene. The gas is combined with oxygen to increase the temperature of the flame.

The torch has hoses that connect to gas tanks. When I’m ready to start welding, I open the valves and ignite the gas as it exits the torch. I can then adjust the valves to adjust the flow of each gas, altering the gas ratio.

Each flame also has several zones called cones. The inner cone is the hottest part of the flame. It’s where the acetylene and oxygen combine.

The outer cone is cooler as it gets more oxygen from the surrounding air. It’s also commonly called the outer envelope or sheath.

So how hot can the gas welding flame get? Depending on the ratio of oxygen to acetylene, the flame can reach a temperature of about 6300 degrees Fahrenheit.

How Many Types of Gas Welding Flames Are There?

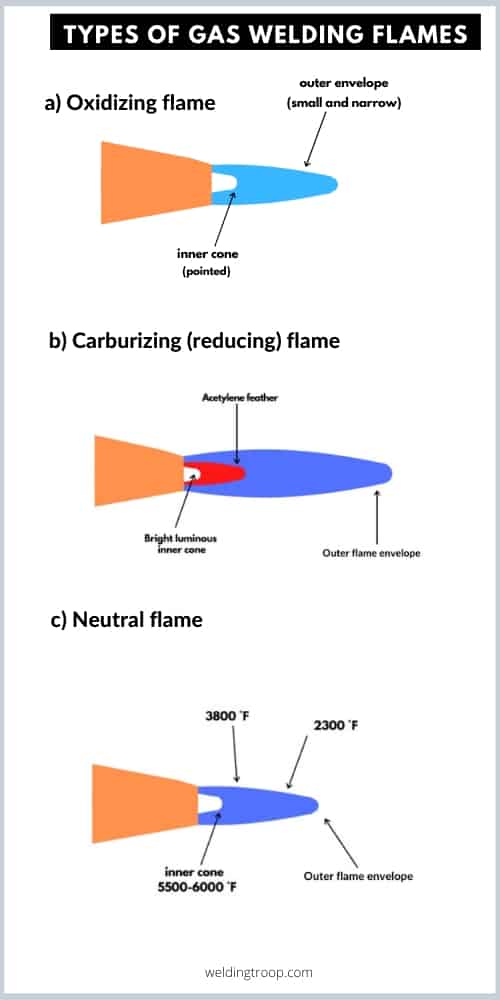

There are three basic types of gas welding flame:

- Neutral: balanced

- Carburizing: excess acetylene

- Oxidizing: excess oxygen

The types of flame are named based on the chemical effect on the material being welded. For example, an oxidizing flame produces oxidation while a carburizing flame produces iron carbide.

A neutral flame has a balanced ratio of gases and no negative impact on the material. Thanks to these features, the neutral flame is the most used option for gas welding but it’s not always the best choice.

As each flame has a different temperature and chemical effect, selecting the right one depends on the materials that you’re working with.

Neutral Flame for Gas Welding

The neutral flame is the starting point for other flames. It has a one-to-one ratio of oxygen and acetylene. Burning all the available gas produces a clean flame.

The inner cone is often bluish-white with a tip that can reach temperatures of about 5850 degrees Fahrenheit. The outer cone or sheath is clear or light blue and has a temperature closer to 2300 degrees Fahrenheit.

The tip of the inner cone is used to heat the parts that you want to weld. It’s the hottest part of the flame. As the metals cool, they join through fusion.

Using equal proportions of acetylene and oxygen creates a cover that prevents oxidation. This also produces carbon dioxide, which shields the metal surfaces.

When Should You Use a Neutral Flame?

Neutral flames are used for most gas welding projects, especially when working with metals that oxidize easily. If you’re welding any of the following metals, start with a neutral flame:

- Copper

- Cast iron

- Stainless steel

- Mild steel

- Aluminum

Neutral flames work with both non-ferrous and ferrous metals. The neutral chemical effect means that it doesn’t promote oxidation or carburization.

Carburizing Flame for Gas Welding

To create a carburizing flame, I first achieve a neutral flame. I then slowly open the acetylene valve to increase the ratio of acetylene to oxygen. As the ratio increases, a white stream extends from the inner cone.

The carburizing flame has three separate flame zones. The inner cone is still bluish-white and reaches a temperature of about 5700 degrees Fahrenheit. The acetylene stream, or feather, is white-hot. The outer envelope is light blue.

The acetylene feather is created because the gas isn’t fully burned by the oxygen. The incomplete combustion also produces excess carbon, which insulates the flame and reduces the temperature of the inner cone.

When Should You Use a Carburizing Flame?

A carburizing flame produces a carburizing effect, making it suitable for the following metals:

- Carbon steel

- Lead

- Aluminum alloys

- Oxygen-free copper

Carburizing flames are best suited for working with materials that oxidize easily, such as oxygen-free copper and aluminum alloys. It’s also the preferred choice for working with lead and high carbon steels that require surface hardening.

Using a carburizing flame removes oxygen and adds carbon. It may also produce carbide, which hardens the surface. This makes the metal more brittle and prone to cracking.

When working with iron or steel, the carburizing effect may limit its ability to bend or stretch. Avoid using this flame with mild steel or iron.

Oxidizing Flame for Gas Welding

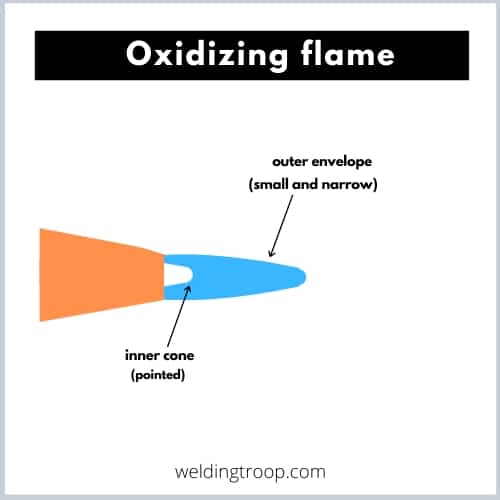

An oxidizing flame has less acetylene and more oxygen. The excess oxygen allows the gas to burn quickly. As it doesn’t need to travel as far, the inner cone can reach hotter temperatures.

With an oxidizing flame, you get a small inner cone that becomes slightly purple as the temperature increases. The outer envelope is small and narrow.

Oxidizing flames also produce a distinct hissing sound as you open the oxygen valve. When adjusted properly, the inner cone can reach 6300 degrees Fahrenheit, making the oxidizing flame the hottest flame for gas welding.

When adjusting the neutral flame to create an oxidizing flame, the flow of oxygen is increased until the inner cone is about one-tenth of its original size.

When Should You Use an Oxidizing Flame?

The short, hot flame oxidizes certain metals, making it unsuitable for many welding applications. When the hot flame reaches steel, it melts the metal and has an oxidizing effect. The metal also becomes more porous and brittle, which may cause it to break easily.

I’ve found that oxidizing flames are still useful for working with some metals, including:

- Cast iron

- Manganese steel

- Copper

- Zinc

- Bronze

- Brass

Avoid using an oxidizing flame with metals that contain iron as iron oxidizes quickly. Copper, bronze, brass, and zinc contain little or no iron.

While iron oxidizes easily, an oxidizing flame still works for cast iron. Unlike other metals with high iron content, cast iron is resistant to oxidation.

What Type of Gas Should You Use for an Ideal Flame?

Acetylene is the most used gas for producing the types of gas welding flames discussed but it’s not the only option. MAPP and hydrogen are often listed as alternatives to acetylene.

Acetylene has a “triple bond” that uniquely bonds carbon atoms. When other gases reach their ignition temperatures, the bond breaks. The gases then absorb energy. When the bond breaks in acetylene, it releases energy. This allows acetylene to achieve higher temperatures.

Compared to other gases, acetylene also has fewer oxidizing characteristics. However, it also ignites easily. MAPP was created as a safer option.

MAPP gas is a liquified petroleum gas combined with propane and acetylene. It can be shipped in smaller containers compared to standard acetylene, has a higher ignition temperature, and works with much higher pressures.

The drawback to MAPP is the temperature. The flames produced using MAPP achieve lower temperatures compared to acetylene flames. It’s not suitable for use with most steels but may work well for aluminum.

Hydrogen is another gas that welds aluminum easily. As with MAPP, hydrogen flames reach lower temperatures and work with higher pressures.

Unless you plan on fusing aluminum, stick with acetylene. The low temperature and withdrawal rate keep MAPP and hydrogen from properly fusing harder metals.

While MAPP and hydrogen aren’t the best choices for gas welding, they’ve become popular options for gas cutting. When used with a high-pressure torch, MAPP and hydrogen provide cleaner cutting.

The lower temperatures also make MAPP and hydrogen common choices for heating, bending, and brazing.

Common Ratios for Producing Oxyacetylene Flames

Neutral gas welding flames have an equal mixture of oxygen and gas. Carburizing flames have less oxygen while oxidizing flames contain more oxygen. So how do you determine the ratio?

No matter the project, start with the neutral flame. The carburizing flame and oxidizing flame are created by increasing the release of acetylene or oxygen after achieving a neutral flame.

I created the following list to break down the typical ratio of oxygen to acetylene for each flame:

- Carburizing flame: 0.8 to 1.0

- Neutral flame: 0

- Oxidizing flame: 1.0 to 2.5

As you increase the flow of acetylene, the distinct feather starts to extend from the inner cone. The feather should reach about two or three times the length of the inner cone. Preventing the gas from fully combusting also lowers its temperature.

If you need an oxidizing flame, you increase the flow of oxygen instead of increasing the flow of acetylene. The extra oxygen produces the oxidizing effect and allows the gas to combust faster, resulting in higher temperatures.

How Do You Create a Neutral Flame for Gas Welding?

As the neutral flame is the starting point for creating other flames, it’s the first flame that I learned how to produce. Start by adjusting the regulators.

The oxygen cylinder and acetylene cylinder each have a regulator with two gauges. One gauge tells you the remaining pressure while the other displays the working pressure.

Adjusting the screw on the regulator adjusts the working pressure, allowing you to increase or decrease the flow of oxygen or gas.

Before lighting the torch, stand away from the front of the regulators and slowly open the oxygen cylinder and then the acetylene cylinder. Turn the regulator screws to adjust the pressure settings.

With the pressure on the regulators set, you can light and adjust the torch. Open the acetylene valve a quarter turn and ignite the torch. Slowly open the oxygen valve until you see three distinct zones.

You should see the inner cone, the feather-shaped acetylene cone, and the outer envelope. Continue to slowly open the oxygen valve until the feather disappears into the inner cone. You now have a neutral flame.

To create a carburizing flame, slowly open the valve on the acetylene cylinder until the feather reaches two to three times the length of the inner cone. To create an oxidizing flame, increase the flow of oxygen until the inner cone is about a quarter of its original size. You should also hear the distinct hissing sound.

Conclusion: types of gas welding flame

Gas welding isn’t the preferred welding method for industrial applications as arc welding provides greater efficiency and less oxidation. However, gas welding is still a popular choice for small garages and hobbyists.

The equipment for gas welding is much cheaper and more portable compared to arc welding gear. It’s an older technique and still a reliable way to fuse metals.

If you’re interested in using the older welding technique, you need to understand the basic types of flames for gas welding: neutral, carburizing, and oxidizing.

Here, you can find an article from our website about how long does it take to learn welding?

A neutral flame has no chemical effect on the metal other than fusing the parts. Carburizing flames have a carburizing effect, hardening the metal. Oxidizing flames produce oxidation.

In the end, when you’re not sure what type of flame to use for your project, start with the neutral flame. It’s suitable for most welding applications. If the metal starts to crackle or oxidize, you likely need more of a carburizing flame. If the metal hardens too quickly or becomes brittle, you may need an oxidizing flame.

Recommended Reading

Do Welders Make Good Money? | Highest Paying Welding Jobs

Advantages of Being a Welder >>Salary, Working Hours | Worklife Balance

Here are some of my favorite tools & equipment´s

Thank you for reading this article. I hope it helps you find the most recent and accurate information for your welding project. Here are some tools that I use daily and hope you´ll also find helpful.

There are affiliate links, so if you do decide to use any of them, I´ll earn a small commission. But in all honesty, these are the exact tools that I use and recommend to everyone, even my own family. (NO CRAP)

To see all my of most up-to-date recommendations, check out this resource that I made for you!