Welder duty cycle is an essential aspect of welding equipment performance. It is a term that defines the percentage of operating time within a specific period during which a welder can safely produce the required welding current.

What is a welder duty cycle? duty cycle as time ratio, or the percentage of safe welding time versus the time it takes to recharge. The percentage given is the amount of time it can operate at maximum heat before it has to cool down.

In this article, we will delve deep into the concept of the duty cycle, its importance, the factors affecting it, and how it varies across different welding processes. We will also discuss the consequences of exceeding the duty cycle and how to evaluate a welder based on this parameter.

Table of Contents

What is a Welder Duty Cycle?

A welder duty cycle is the percentage of a 10-minute interval during which a welding power source can output the rated amperage continuously without overheating.

It helps determine how long a welder can operate at a particular amperage before needing to cool down. For instance, a welder with a 60% duty cycle at 200A can output 200 amps for six minutes before it needs to rest for the remaining four minutes of the 10-minute interval.

Importance of Duty Cycle in Welding

The duty cycle is a crucial aspect of welding equipment because it gives an idea of the kind of jobs a welder can handle. For example, hobbyist welders typically have shorter duty cycles, while professional units have much longer ones.

Exceeding the duty cycle limit can cause the welder to go into thermal overload mode, leading to a decrease in weld quality and potential damage to the equipment.

Factors Affecting Duty Cycle

Several factors can affect a welder’s duty cycle, including:

- Ambient temperature: The duty cycle is usually determined at a specific ambient temperature. If the working environment has a higher temperature than the one used for testing, the duty cycle might decrease.

- Machine cooling mechanisms: Welders with internal fans can cool down faster, thereby improving their duty cycle.

- Equipment specifications: Welding machines with higher power ratings and better-quality components are likely to have a higher duty cycle.

- Welding process: Different welding processes, like MIG, TIG, and stick welding, have varying demands on the equipment, which can influence the duty cycle.

- Maintenance and cleanliness: Dust and debris can block airflow vents, leading to faster overheating and a reduced duty cycle. Regular maintenance and cleaning of the welder are essential to ensure optimal performance.

- Humidity: High humidity can affect heat dissipation, reducing the duty cycle of the welder.

Duty Cycle Rating Standards

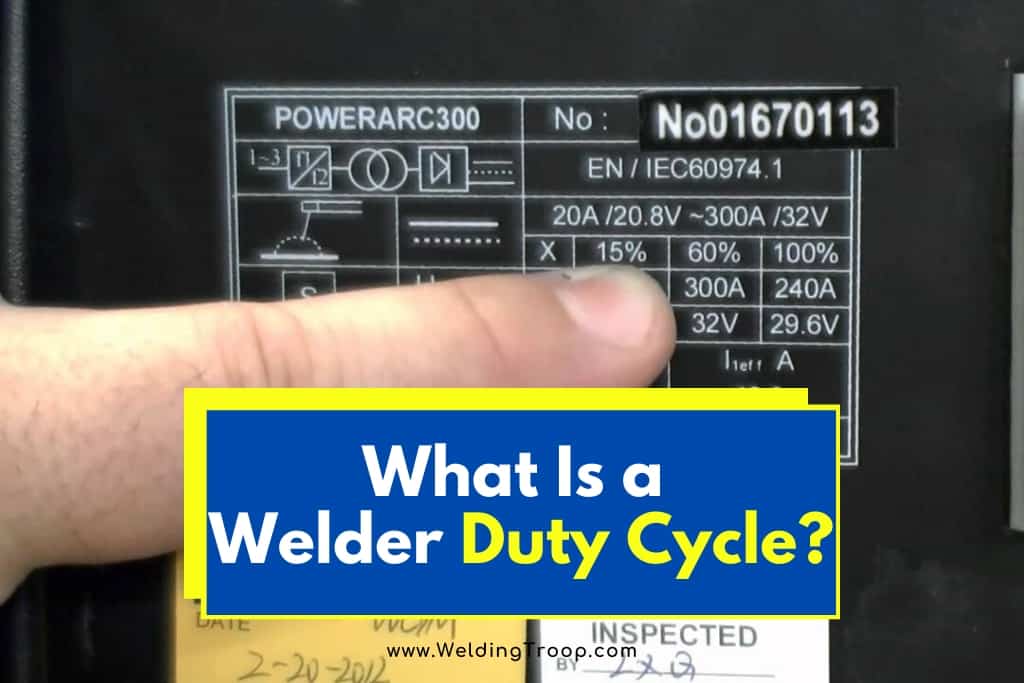

It is essential to note that duty cycle ratings can differ across manufacturers, as they may use different testing methods. The widely accepted standard for testing duty cycle is the European standard EN60974-1 and the Australian standard AS60974-1 (based on the EU standard), which designate a 10-minute timeframe for testing at an ambient temperature of 40°C after at least two thermal overloads.

When comparing welders, ensure that they follow the same test standard to avoid misleading marketing tactics and inflated duty cycle values.

Duty Cycle for Different Welding Processes

Duty cycles vary across different welding processes like MIG, TIG, and stick welding due to their inherent differences and demands on the equipment.

MIG Welding Duty Cycle

MIG welding is a continuous welding process that uses automated wire feeding, allowing for longer periods of uninterrupted operation. As a result, MIG welding machines typically have longer duty cycles.

When choosing a MIG welder, consider the thicknesses you want to weld and the amperage needed, and opt for a machine with at least a 60% duty cycle at the required amperage.

TIG Welding Duty Cycle

TIG welding is a slower process that requires fewer stops, making it suitable for high-duty cycle welders, especially when welding thick sections. However, most TIG welding applications require less than 100-130A, and many machines can run at a 100% duty cycle at such low loads. Also, using a TIG foot pedal or a pulse function can help improve the duty cycle length by reducing the average continuous load.

Stick Welding Duty Cycle

Stick welding allows for frequent pauses during the welding process, as the electrode needs to be replaced, and slag needs to be removed. These pauses give the machine time to cool down, meaning that stick welders can have a shorter duty cycle. A 150A stick welder with a 40% duty cycle is generally sufficient for most jobs.

Consequences of Exceeding Duty Cycle

When the duty cycle of a welding machine is exceeded, the welder may trigger its thermal overload safety feature, shutting down the power and protecting the internal components from damage. However, some welding machines do not have this safety feature, and they may catch fire or damage their sensitive parts.

Exceeding the duty cycle limits can also reduce the welder’s lifespan and lead to equipment failure. It is essential to avoid constantly pushing the machine to its limits to prevent damage to its internal components.

Evaluating a Welder Based on Duty Cycle

While duty cycle is an important parameter to consider when choosing a welder, it is not the only factor. Other aspects to take into account include the welder’s amperage output range, included functions, portability, build quality, and warranty.

Always prioritize warranty over duty cycle, especially if a manufacturer claims a high duty cycle but provides a short warranty period.

Remember that duty cycle ratings can differ across manufacturers, and it is crucial to compare welders that follow the same test standard. A higher duty cycle welder is preferable if your budget allows, but if you don’t plan to weld often or make long beads, a less expensive machine with a shorter duty cycle may suffice.

That What and Where of Duty Cycles

Let’s get the most basic question out of the way first – what exactly is a duty cycle? We already know that it’s responsible for helping to cool your welder, but what is it and how does it go about doing that?

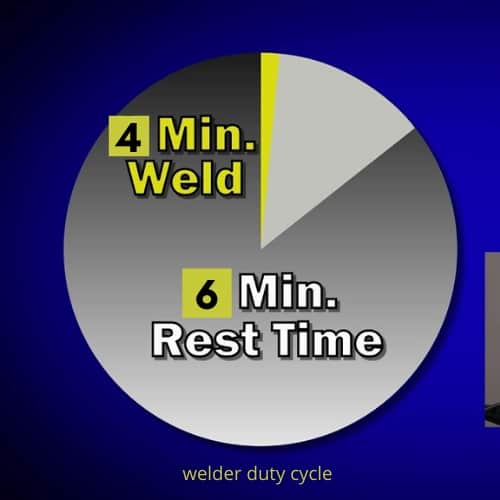

It is best to think of your duty cycle as time ratio, or the percentage of safe welding time versus the time it takes to recharge. The percentage given is the amount of time it can operate at maximum heat before it has to cool down. For example, if your unit has an amperage of 250 and a duty cycle of 40%, it can operate at 250 amps for 4 out of 10 minutes, while the other 6 has to be spent allowing it to cool down.

Obviously, the higher the duty cycle, the faster your welder can cool down and recharge, allowing you to get back to business.

It is also important to note that your duty cycle is apt to cool and restart the machine at various rates depending on the amperage. The higher the amperage, the lower the percentage, and thus the more time it takes for the duty cycle to cool it down and allow you to weld safely again.

While it may seem like a hassle to have to keep stopping and starting to get your welder running again, it is necessary to prevent the unit from overloading, which can be disastrous.

There are other factors besides the unit itself which come into play, starting with the ambient temperature. This contributes to the unit’s temperature in the form of external heat, so obviously the higher the ambient temperature, the harder it is for the duty cycle to cool the unit. As such, it is usually a good idea to weld in as cool and climate-controlled an area as possible, so as to avoid putting extra strain on the duty cycle.

What Is Welder Duty Cycle and Why Should You Care? >> Check out the video below

Testing the Duty Cycle

Given its importance, it should come as no surprise that most welders test their duty cycles, especially on a new machine.

In addition to the unit’s working internal temperature and ambient external temperature, testing also involves taking into consideration whether the unit is “fresh” (that is, cool and just turning on) or has already been warmed up from previous usage. In the latter case, your unit will already be warm, so it’ll likely take even longer for it to cool down to a safe temperature.

Different duty cycles make use of different duty cycle ratings. For example, many machines in Europe and Australia are tested according to the European Standard EN60974-1. Make sure that you are testing your duty cycle with machinery that matches your unit type and origin.

Judging Performance

If you read reviews of MIG welders, chances are good they’ll include references to the unit’s duty cycle. That begs the question – just how important of a performance evaluator is the duty cycle?

That depends on what you consider “important,” of course, and what you’re looking for in a unit. If what you care about most is the portability of a unit, for example, the duty cycle is likely to be of little to no importance as it really has no bearing on that.

On the other hand, however, if safety is one of your biggest concerns – and, to editorialize, it really should be, especially if you’re a newcomer just learning how to control your welder – the duty cycle is hugely important. An effective duty cycle is one of the main things standing between you and a major safety hazard, to put it mildly.

What’s more, if you care about the unit’s heat and efficiency, the duty cycle is also of massive importance. A unit can really only get as hot as is safely manageable. That means a duty cycle that is up to the task of cooling a unit once it reaches those incredibly high temperatures and letting it recharge quickly so you can get back to welding.

The rapidity of the recharge time is also why the duty cycle is important if you’re looking for a “fast” welder – the faster the recharge time, the faster your unit can weld something without overheating.

Conclusion

Understanding welder duty cycle is essential to ensure safe operation and optimal performance of your welding equipment.

By considering factors like the welding process, ambient temperature, and equipment specifications, you can select the right welder with an appropriate duty cycle for your specific needs.

Always ensure that the welder you choose follows the widely accepted testing standards and prioritize warranty over duty cycle when making your final decision.