Color codes are incredibly important when welding. When you know how to identify the gases you’re using based on the color of the hose, you can remain as safe as possible when welding.

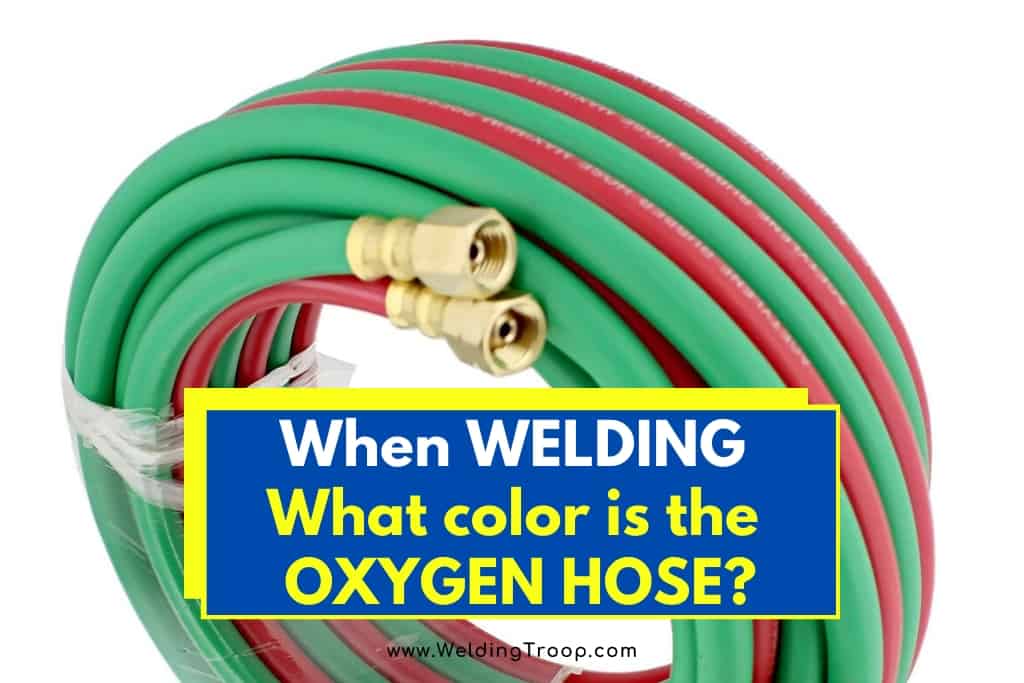

What color is the oxygen hose when welding? Oxygen will be in the green hose. However, this may differ based on the country you live in and may not match the color of the supply tank.

You must be aware of the standards where you’re welding, however, as some rules are quite variable, They can change based on the type of welding you’re doing and whether you’re identifying the gas based on the hose or tank color. Below are some guidelines on how to identify the types of welding gases by the hose color.

Table of Contents

Meaning of Hose Colors in Welding?

The colors of the hoses used during welding are extremely important, and not just for show. It is critical that you not only know the colors of these elements but why they are assigned the colors they have. This is important not only for ensuring proper completion of the job but in maintaining your safety when working.

There are many different techniques in welding, each requiring different tools to make the job progress correctly. In addition to these varying tools, every welding technique requires a special gas as well.

Some of the most commonly used gases in the U.S. include acetylene and propane. These are used as fuel, and therefore must be differentiated from the oxygen supply (which would be green) by the color red.

These distinct hoses will also be distinguished by different threads:

- Red hoses are designed with a left-handed thread

- Green hoses are designed with a right-handed thread

You may also be using inert gases. These are necessary for shielding purposes in several types of welding techniques and are distinguished by a black hose.

(Note: These colors may vary according to the country you are working and/or living in. Review any laws regarding your work to ensure that you are in full compliance with regulations. Moving forward, we will be discussing colors in the context of the U.S.)

Identifying Welding Hoses

The hoses for welding gases are typically sold in pairs – one for fuel gases and one for oxygen. At times, they may be designed with the added benefit of them being attached.

Presumably, this is to aid users in the organization of their welding equipment. Although it will certainly help you, you must still keep these pieces of equipment separate. Knowing the color by which to identify your gas will help you do that.

| Welding Hose Color | Gas |

| Red | Fuel Gas |

| Green | Oxygen |

| Black | Inert (Shielding) |

Knowing how to identify your welding hoses is critical to keeping yourself and your workpiece safe from harm. Their physical separation is critically important since it will prevent the two (or more) substances from mixing. For this reason, you must ensure that the proper gas is connected to the appropriate hose.

Welding Gas Tank Colors in the United States

Although there is a color code that gas tanks should adhere to, this piece of equipment is, unfortunately, less likely to follow the standards of uniformity that gas hoses do.

For this reason, it is even more important that you check your gas tanks, as well as the hoses, before beginning work. Some gas tanks are distributed with a printed warning, urging users not to assume that the color is accurate, and to just read the label instead.

The standards of coloring gas tanks are also a lot more inconsistent than those concerning hose. This is part of the reason why the colors vary so often. For instance, you may find oxygen in a green tank once, but gray, another time. Acetylene is another that can get quite mixed up as well, as it can be red at times, and purple or blue, another.

Always check the printed label to be sure of what type of gas you are using.

Welding Hose Colors Around the World

The color code of welding hoses and gas supply tanks will vary according to the country you are working or living in.

In the U.S., as we’ve established:

| Hose Color | Gas |

| Red | Fuel Gas |

| Green | Oxygen |

| Black | Argon, Helium, Carbon dioxide, Oxygen |

- Fuel gases are red

- Oxygen is green

- Shielding gases are black. Types of shielding gases include:

- Argon (Ar)

- Helium (He)

- Carbon dioxide (CO2)

- Oxygen (O2)

You need to be careful, though, if ever you find yourself working in another country, however, as laws will change and therefore dictate different color assignments to certain gases. (Even with those regulations in place, it’s not guaranteed that the gases will be packaged correctly. For this reason, you should always read the label of the supply tank you are using before you begin the weld.)

In Japan, for example, welders operate by a 4-color system for distinguishing the hoses.

- Oxygen is blue

- Acetylene and fuel gases, apart from a few specific types, are distinguished by red

- Shielding gases are also distinguished by green

Gas supply tanks can differ quite drastically from hose colors. For example, tanks in Australia are assigned many more color designations, more assigned to specific gases than categories of gases. (Tank colors may vary slightly from hoses, however, they do not always necessarily have more colors to choose from.) For example:

- Carbon dioxide can be recognized as green-grey

- Argon is peacock blue

- Oxygen is black

- Hydrogen is red

The list goes on. Hoses in Australia, on the other hand, follow these standards:

- Oxygen is blue

- Air, nitrogen, carbon dioxide, argon are all black

Even with these rules, there are still differences. For instance, there are regulations that assign pressure regulators the color black for oxygen, instead.

The bottom line is that you must be highly aware of the type of gas you’re using to avoid injury or damage to the metal workpiece. This requires not only recognition of the listed color designations, but also confirmation of that color identity by the printed label.

Types of Welding Techniques

There are many different types of welding techniques, most of which follow the same guidelines in terms of labeling and identifying fuel and shielding gases. These techniques include:

- Gas Metal Arc Welding (GMAW): This technique requires an electrode that is continuously fed through a welding gun. Heat s generated from the electric arc produced between the material and the electrode. For this, you need only a shielding gas. This is most often used for:

- Magnesium

- Carbon steel

- Stainless steel

- Copper

- Gas Tungsten Arc Welding (GTAW): Also known as Heliarc welding, this technique also generates heat on the workpiece by use of an electrode. An external gas supply is required here as well, and some of the most common gases to use include argon and a mixture of argon and helium. This is best applied to:

- Aluminum

- Copper

- Magnesium

- Nickel

- Shielded metal arc welding (SMAW): Commonly referred to as Stick, this shielded metal arc welding technique requires an electrode. This one is quite different from the previous two, however, in that it does not require the use of shielding gas, so you can use this even in various environmental conditions (wind, rain, etc.). (Unfortunately, this technique produces quite a bit of waste for inexperienced users.)

Two additional methods, atomic hydrogen welding (AHW) and gas tungsten arc welding, are distinguished for their unique applications that rely more heavily on the use of gas than those listed above.

Learn More About different Welding processes – Here, you can find an article from our website: 9 Different Types of Welding Processes & Their Advantages

AHW, invented by Irving Langmuir, has unfortunately been replaced by many gas metal arc welding methods but remains in practice with specific applications (tungsten workpieces, for example). This requires two electrodes to be placed in a hydrogen atmosphere. The hydrogen molecules are then deconstructed and combined to produce a combustion that reaches up to 3000֯ Celsius.

Gas metal arc welding, on the other hand, uses an electrode with no coating and shielding gases. The shielding gas is most often a mixture of any of the following:

- Helium

- Argon

- Carbon dioxide

Once you understand the gases required in these welding practices, you’ll know what to expect from the color assignments. If the colors do not match the standards that are in place, double check the printed label for both the hose and tank to maintain safety and ensure the quality of the weld.

Recommended Reading

Is Welding Oxygen the Same as Medical Oxygen?

Differences between Plasma Cutter and Oxy-acetylene Torch Cutter