You will soon learn that you need a workspace on which to do your welding Working with hot metal, electric arcs and weld splatter require something a bit more durable than most wooden workbenches. A welding table specifically built for that job can be a welcome addition, especially when a complicated project is starting to go together, and you begin to understand why welding tables have holes.

Why do welding tables have holes? Welding tables have holes to give the welder more control and options when setting up a welding job by allowing

- Full use of the tabletop to clamp

- The easy placement of jigs, stops, and clamps

- Perfect alignment of pieces and parts

Welding tables are available in almost any style and size you can imagine. Some have adjustable legs to vary the working height. Even the holes come in different sizes.

Threaded holes are available to use with special jigs and clamps. Slots are available on some tables to allow the welder to more easily position the clamps and jigs. Choosing a welding table can be a bit bewildering. Here’s a guide to make the choice easier.

Table of Contents

Finding that Perfect Welding Table

Before you head out to the welding supply store to purchase a welding table, take a few minutes and consider the features you need, the types of projects you have planned, and your budget. Doing a little research and planning beforehand is important to make sure you have the features and options that fit your job requirements.

There are a few features that you should consider.

- Your Projects – What kind of projects do you build? How big are they? How much weight do you anticipate putting on your welding table? What kind of materials do you normally weld? All these questions figure into making decisions about the next few features you should think about.

- Quality – The quality of construction of your welding table is the key to several factors. Durability is one. Higher quality tables will last longer in a shop environment. Better quality tables are also more prone to be accurate and square. If you opt for a portable welding table, good design will make it easy to use and store.

Learn More About Welding Safety – Here, you can find an article from our website about: Personal Protective Equipment for Welders – PPE | List, and Requirements

- Size and Weight – These two go together like bread and butter. If your projects require you to go to the job site instead of bringing the work to your shop, size and weight come into play rapidly. If you build large, heavy projects, a bigger and heavier table may be required. Try to fit the size and weight of your welding table to the needs of your job.

- Height – If at all possible, buy a welding table that has adjustable legs. Being able to adjust the height of your working area can make your life much more pleasant. It is much more ergonomic to adjust your workspace to your requirements than trying to adjust your position to the workspace. This can lead to fatigue and other physical problems.

- Accuracy – A quality welding table will be accurate, square, and flat. The holes and slots will be precisely milled or drilled. The edges of the table will be square, as will the corners. The top surface should be milled flat and should be designed to stay flat.

- Budget – We all must consider the budget. The object is always to find the best trade-off in features and quality and budget constraints. Our advice is to stretch your budget, if possible. The better-quality welding table you can buy, the better it will perform for you in the long run.

Holes and Slots

Most commercially available welding tables will come with holes and slots in the welding tabletop to make using jigs, stops and clamps much easier. There are some issues with the addition of holes and slots to a welding tabletop that you should understand.

- The slots may tend to warp when the tabletop heats up. – Welding generates a lot of heat. That’s the way the whole system works. That means your welding table is going to absorb a lot of heat as well. Long slots can warp and drift during repeated heating and cooling cycles.

- The whole hole problem – Tables with slots and holes tend to let things fall through. Soapstone have an annoying habit of falling through slots every time it is laid down on the table. Slag, shavings, and sparks can fall through holes in the welding tabletop, making the underside mostly useless for storing anything.

- The accessory fit situation – If your welding tabletop is pre-drilled and slotted and the holes are tapped and threaded, you are locked into using only those clamps and accessories that fit those holes, slots, and thread patterns. There are some industry standards, and we suggest you find a table that offers the most robust selection of accessories possible.

About the Accessories

Buying the welding table is just the beginning. It won’t be long before you want all sorts of accessories for your welding table. In time you may even be machining and building your own stops and jigs for your welding table. The accessories and tools that are available to make your welding jobs easier include:

- Clamps – Clamps come in every imaginable style, shape, and design. You can find a solution to your clamping needs with a quick search on the internet. The basic styles of welding table clamps you can source are:

- Squeeze type clamps

- C-Clamps

- Screw type clamps

- Lever clamps

- Stops – Stops come in different lengths. These handy accessories can be had in round styles or square styles. Stops are useful for aligning parts and holding them in place as the initial welds are made, ensuring a square joint.

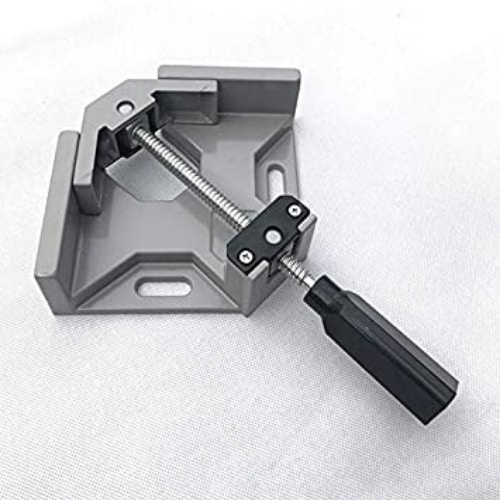

- Right Angle and adjustable angle guides – These versatile clamps allow you to set up a job with odd angles that will stay in position until you get the weld completed.

- Vices – Various styles of vices are available that will use the holes and slots in your welding table for quick mounting and dismounting as required. A vice can take up a lot of room on a worktable. Being able to have a vice when it is needed can be a big plus.

- The Other Things – There are the other things to look for as part of your welding table accessories. Many welders like to have a place to hang their welding gun or torch. Baskets and racks for accessories, tools, and small parts are also handy.

The DIY Option

There is always the option to build your own welding table. Welding tables are, by nature, metal projects, and we are welders. Building your own table to your own specifications is the first big project many welders undertake.

Designing and constructing your own welding table allows you to make it fit your needs and job requirements perfectly. There are a few challenges to building your welding table.

- The Tabletop – Getting the top prepared and making sure that the piece of metal is square, the corners are true, and the edges are perpendicular to the top can be a challenge.

- The Frame – You must make sure that the frame is perfectly square and true. It should also be designed to be rigid enough to hold the table without allowing bending or flexing when weight is put on the top.

- Holes and Slots – Drilling or machining the holes and slots in your table require precise machining. Specialized tools may be necessary. Make sure you can access these tools before you start the process.

Setting the Table

A good welding table can make the job of jigging up and welding a project faster and easier. Finding the table that best suits your needs and your job requirements can be daunting. We hope that the information in this article makes the process a little easier and has helped you understand what to look for in a good welding table.

Recommended Reading

What Gases Do MIG Welders Use >> Welding Shielding Gas | Complete Guide

Can You MIG Weld in the Rain or when it’s wet?

How to Build a Welding Table >> Tutorial Video