In the world of welding, you may have come across the 8010 welding rod and wondered what its exact purpose was and if you should consider using one. If you are interested in welding, you may be familiar with the need for various tools for accomplishing different types of welds. The 8010 welding rod is a particular welding tool that is useful for a specific type of welding.

What Is An 8010 Welding Rod Used For? An 8010 welding rod is specifically used for vertical down welding and out-of-position welding techniques for steel pipes up to 80 Ksi tensile strength, although it can be employed in all welding positions if desired.

What Is An 8010 Welding Rod?

According to the welding company PhiLARC, an 8010 welding rod is a high cellulose electrode that permits vertical down welding on high tensile strength steel pipes. Due to the fast freezing slag, it is easier to control the shape and size of the weld and is thus well suited for these situations.

The term rod, when applied to shielded metal arc welding, is an informal way of referring to a welding electrode. As such, the 8010 welding rod is also known as an 8010 welding electrode in some welding communities.

The 80 designation indicates it is suitable for high tensile steel of 80 Ksi. This steel is remarkably strong with good corrosion resistance and is easily weldable with the right equipment and techniques.

The 8010 welding rod has a steady, concentrated arc that allows for a highly fluid weld puddle and good penetration. The cellulose nature of the electrode means its main component is made up of organic material, such as paper.

These organic electrodes are able to penetrate much deeper than other electrodes, making the 8010 rods a perfect choice for high tensile strength steel.

In order to get professional-quality welds, it is important to understand the equipment available and how to use it to your advantage. In the world of shielded metal arc welding, there are often specific tools to accomplish a job, so you need to know what materials you are working with and what sort of weld you are attempting in order to achieve the best result.

How Do I Use An 8010 Welding Rod?

The 8010 welding rod is used for vertical down welding and out-of-position welding. Start by generally cleaning the intended welding area of any possible contaminants.

For best results, the Inweld Corporation recommends preheating thicker pipes to temperatures of 300-500 degrees Fahrenheit.

On the initial pass, also called the root pass, use a drag technique while pressing the electrode firmly against the joint. It is advisable to deposit the second pass as soon as possible after the root pass.

A slight weaving, stitching technique will result in a better weld by incorporating the sides of the weld pool into the base welding material, but do not go wider than three times the diameter of the electrode. The whipping technique is not advised.

Some welding communities suggest tilting the electrode at a 45-degree angle in the direction of travel if you are welding flat or horizontal joints. For vertical welding, it is suggested to hold the rod at a 15-degree angle in the direction of travel.

The current of the 8010 welding rod should be kept high enough so as to minimize slag and weld defects such as wagon tracks or worm tracks.

If the voltage is too high, hydrogen is more likely to get trapped in the slag and cause defects. Allow the weld to air cool before attempting to remove slags.

What Is Vertical Welding?

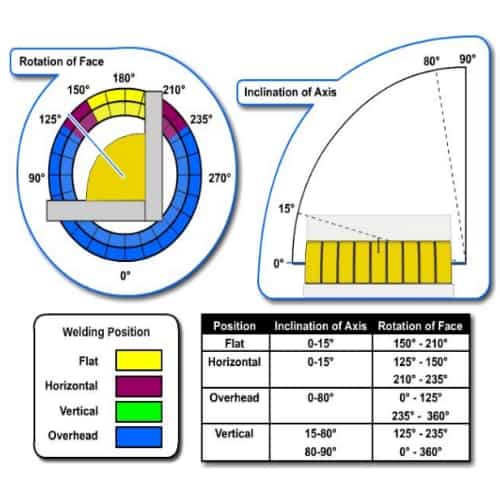

According to the Steelworker Volume 01 Construction Training Manual, vertical welding is a weld that is placed on a vertical surface or a surface that is inclined 45 degrees or less. Pipelines frequently require vertical welding, as well as buildings and some tank welding.

Vertical welding is considered to be more challenging than horizontal or flat welding because you must take into account the force of gravity while working. As you try to weld, gravity will pull down the molten metal, also called slag. If you don’t work with the proper equipment or aren’t adequately trained, your vertical welds may be weak and sloppy.

In order to weld vertically, it is necessary to use a welding rod that has fast-freeze or fill-freeze electrodes. This will allow minimal distortion of the slag due to gravity and better overall control of the shape and the size of the weld.

Vertical down welding is when you weld starting at the top of the weld joint and progress down to the bottom. Vertical up welding is when you start welding at the bottom of the weld joint and progress up to the top.

What Is Stick Welding?

Stick welding, also called Shielded Metal Arc Welding, is a form of welding that utilizes electricity to melt an electrode (also called the stick or rod) and fuse two pieces of metal together. While the seam between the metal is being created, the electrode also fills the joint with filler metal material.

Stick welding requires several pieces of equipment:

- An electrode/rod holder, also referred to as a stinger

- A constant voltage power supply

- A ground clamp

- Welding electrodes/rods, such as the 8010 welding rod mentioned previously

Stick welding can use varying amounts of power. Varying the current strength can directly influence the melting rate, and thus it is important to control the power if you are wanting to make consistent, acceptable welds.

Choosing different types of electrodes can allow for better welding of different types of metal as well as variable penetration rates.

What Is MIG Welding?

MIG welding is a form of arc welding that utilizes a welding gun which holds the electrode and emits a shielding gas over the weld pool to help prevent contamination. MIG stands for “metal inert gas.” This refers to the shielding gas used in the process, which is usually a blend of argon, helium, or carbon dioxide gas.

Another term for MIG welding is gas metal arc welding (GMAW) or wire welding. The shielding gas essentially protects the molten metal of the weld from being contaminated by reactive particles in the surrounding atmosphere.

While argon gas is the most common, it has a slower welding speed and lower heat. Helium gas results in a faster weld with deeper penetration and increased heat.

This form of welding can be useful for welding two different types of metal together as long as the two materials have similar melting points and compatibility. MIG welding will require:

- A constant voltage power supply

- A wire feeder (either add-on wire feed, suitcase wire feed, or spool feed)

- A MIG gun

- A gas regulator

- Hoses and a ground clamp

Choosing the type of wire feeder will depend on what sort of welding you wish to accomplish and how much welding you intend to do.

Add-on wire feeders are more for specialty jobs, found in factories and shops that do extensive welding jobs. Suitcase welders are more common for amateurs or short term jobs.

Spool feeders are found on specific types of MIG guns, usually best for anyone welding aluminum due to the short distance the wire crosses.

MIG welding has other advantages, as well, including a fast welding speed and the ability to be used in any welding position.

According to Gene Mathers in his book The Welding of Aluminum and Its Alloys, MIG welding is the most commonly used manual arc welding process for aluminum.

What Is TIG Welding?

TIG welding is similar to MIG welding except the electrode utilized is made of tungsten and is non-consumable. The tungsten electrode melts the base metal and the weld is protected by a shielding gas, usually argon.

The TIG welding process uses an electric torch while the tungsten filler is directed into the welding joint. TIG welding units allow for the temperature to be gradually increased and decreased, meaning a softer start and stop process on the weld. This allows for easily adjustable heat levels while working.

The equipment needed to perform TIG welding is different from that required for stick or MIG welding. It includes the following components:

- A tungsten electrode

- A constant current welding machine (preferably one specifically for TIG welding)

- A torch or electrode holder

- A shielding gas supply unit

- A filler metal rod

The tungsten electrode used can vary in regard to its composite materials. Electrodes made of pure tungsten tend to be cheapest but can be contaminated more easily and don’t have as good of conduction as other options.

Often, a core of 1 to 2% thoria is placed within the tungsten to improve conductivity and resist contamination. A core of 0.15 to 0.40% zirconia can also improve conduction and lessen contamination risk and it is slightly less expensive.

Advantages and Disadvantages of Stick Welding Compared to MIG and TIG Welding

One of the main advantages of stick welding is that it is able to be used in more flexible conditions than MIG or TIG welding. MIG and TIG require clean, contaminate free metal in order to weld, and so time must be taken to remove any rust or paint before proceeding. Stick welding does not require this additional step.

MIG welding tends to be better looking, with less splatter and a smoother seam finish but it requires more preparation of the metal. MIG and TIG welding are also better for welding thinner metals. Stick welding often will burn through thinner metals and is more ideal for thick, high tensile strength materials. MIG welding also does not require pausing work in order to replace a used-up electrode.

Advantages of stick welding include the following:

- No need to clean paint or rust at the welding site

- Ability to change electrodes to better suit welding of different metal types

- Not affected by wind

- Ground clamp can be attached far from the welding point and still achieve a good amount of power

- It is much more cost-effective than TIG welding, especially for thicker metals

In contrast, there are a few downsides to stick welding when compared to MIG and TIG welding:

- The slag needs to be chipped away before painting or additional welding

- It can burn through thinner metals

- There is a higher rate of splatter than with MIG and TIG welding

- Welding must be paused to replace the consumable electrodes

- Welds are usually not as smooth and clean as those made with MIG or TIG welding

Depending on what you are intending to weld and how much welding you wish to perform, one welding type may be more advantageous than the others. A stick welding system may be perfectly adequate for your needs, but if you intend to weld mostly thinner metals or need flawless, beautiful welds, a MIG or TIG welding machine might be more suitable.

Here are some of my favorite tools & equipment´s

Thank you for reading this article. I hope it helps you find the most recent and accurate information for your welding project. Here are some tools that I use daily and hope you´ll also find helpful.

There are affiliate links, so if you do decide to use any of them, I´ll earn a small commission. But in all honesty, these are the exact tools that I use and recommend to everyone, even my own family. (NO CRAP)

To see all my of most up-to-date recommendations, check out this resource that I made for you!