I’m willing to bet that, if you aren’t part of the welding profession, the idea of doing so underwater might get you to gasp in shock and disbelief. Sure, you may not know a thing about welding, but you know water and electricity just don’t mix! How on Earth is it possible for you to weld underwater? What is hyperbaric welding, and how can it possibly be safe?

Hyperbaric welding is the process of welding underwater in a hyperbaric chamber, which helps spare you the nasty “shock” that would come from mixing water and electricity otherwise. It is a hugely important skill because there are plenty of settings that require hyperbaric welding, such as dams, oil rigs, ships, and even some nuclear power stations.

Wherever there’s a structure that requires metal fabrication for something beneath the water, underwater or hyperbaric welders can meet the challenge.

Here, you can find an article from our website about 7 steps for avoiding electric shock when welding underwater.

Table of Contents

Hyperbaric Welding History

Hyperbaric welding history dates back to the 1930s when the first hyperbaric welding experiments were conducted by the Russian metallurgist Konstantin Khrenov. However, the first commercial hyperbaric welding project was undertaken by Ocean Systems in the Gulf of Mexico in September 1967.

After Ocean Systems, Taylor Diving became the major player in hyperbaric welding, building the first hyperbaric welding chamber complex at Belle Chasse and completing a pipeline repair off the coast of Brazil.

Today, hyperbaric welding is a specialized field that requires certification in welding, experience in welding, and certification as a commercial diver.

What Is Hyperbaric Welding Process?

Hyperbaric welding is the process of welding at elevated pressures, usually underwater. It involves the maintenance and repair of marine infrastructures submerged in water and is performed similarly to welding on dry land, requiring years of training to gain both the required knowledge and necessary certification from an accredited commercial dive school.

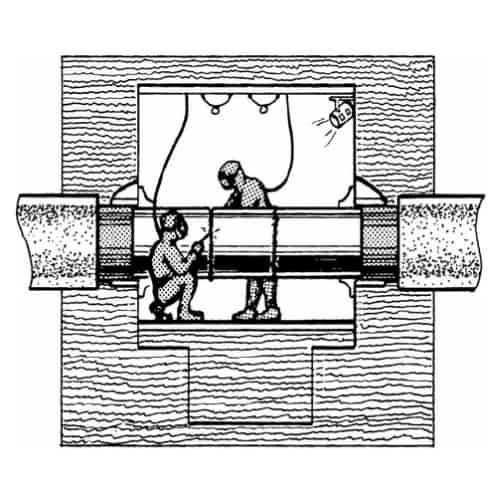

There are two types of hyperbaric welding: dry welding and wet welding. Dry welding uses a dry chamber or habitat, whereas wet welding involves welding in water and is mostly done using Shielded Metal Arc Welding (SMAW) or “stick welding.”

The key to preventing electrocution during underwater welding is the thick layer of gaseous bubbles that the flux or external coating of the electrode creates to cover the weld and shield the electricity from water and other oxidizing compounds.

What Are The Advantages of Hyperbaric Welding?

Hyperbaric welding is a type of underwater welding where the welding is done in a hyperbaric chamber filled with a gas mixture that is pressurized to simulate the conditions of working underwater.

Some advantages of hyperbaric welding are that it allows for welding in a dry environment, which produces higher quality welds since there is no water to cool the welding area.

Additionally, hyperbaric welding allows for the use of more complex welding techniques that are not possible with wet welding, and it reduces the risk of contamination of the welding area.

How To Become a Hyperbaric Welder?

Becoming a hyperbaric welder typically requires a high school diploma or GED, certification in welding, and experience in welding. Additionally, aspiring hyperbaric welders must become certified commercial divers by enrolling in a commercial diving program, passing physical exams approved by the Association of Diving Contractors International, and attending an underwater welding school.

Hyperbaric welding involves welding at elevated pressures, usually underwater, and there are two types: dry welding and wet welding.

Hyperbaric welding allows for welding in a dry environment, producing higher quality welds and allowing for the use of more complex welding techniques

What Does a Hyperbaric Welder Do?

A hyperbaric welder, also known as an underwater welder, performs welding and other related tasks to repair metal components and equipment in fresh and salt bodies of water. They use specialized equipment and techniques to weld in an environment that is much different from traditional welding.

Hyperbaric welders may be employed by marine construction firms, offshore oil rigs, research facilities, federal, state, and local governments, as well as nuclear power plants.

Some of the duties of an underwater welder include drafting, fitting and rigging, underwater cutting, and inspections.

How Long Do Hyperbaric Welders Work?

Hyperbaric welders typically work for long hours and can be away from home for several weeks at a time. On average, they work for 4-6 weeks at a time, followed by a shorter break of 7-10 days. However, the actual work hours can vary greatly depending on the project and location.

Some projects may require insane overtime, with workdays of 10+ hours. The work of a hyperbaric welder involves welding and related tasks in fresh and salt bodies of water using specialized equipment and techniques.

In addition to welding, their duties may include drafting, fitting and rigging, underwater cutting, and inspections.

How Deep Can Hyperbaric Welding Go?

Hyperbaric welding can be performed at depths of up to 300 meters using specialized offshore habitat systems. However, dry hyperbaric welding research is ongoing, and it is expected that it can be used at depths of up to 1,000 meters in the future.

Underwater welders typically work at depths of 30 to 400 feet. The depth of water, type of welding, and experience can affect the salaries of underwater welders.

Hyperbaric Welding Salary

Hyperbaric welding, also known as underwater welding, can offer high salaries depending on various factors such as depth of water, experience, and type of welding.

Welders who work at greater depths can earn higher salaries, with deep divers earning about $30,000 to $40,000 per month.

On average, the annual salary for an underwater welder is around $50,000, with experienced welders making up to $90,000 annually.

However, some commercial divers’ underwater welding salaries can exceed $300,000 annually. The salary range varies based on the experience, certification, and type of welding involved.

Read also >> Types of Underwater Welding (Procedure & Applications)

Read also >> Offshore Underwater Welding Jobs: Description and Salary Details

Underwater Welding 101

As a practice, hyperbaric welding is actually older than you might imagine. It was first pioneered way back in 1932 by the Russian metallurgist Konstantin Khrenov. It works in a similar fashion to conventional, above ground welding insofar as it also involves melting different joints and metal parts together via an arc.

The big difference is, of course, that you are doing so underwater, despite the fact that our intuition would seem to tell us that mixing electricity and water is a very bad idea.

Before you continue reading, here is an article we wrote about the different types of underwater Welding.

Underwater welders are trained in special techniques for controlling the electrical flow of their tools in such a way as to mitigate that risk. As expanded upon below, they do this via dry and wet welding techniques.

These require special training to learn. However, the actual welding process itself is similar in many respects to conventional welding.

As such, if you’re already a welder or commercial diver, you’ll have a leg up in training, and be able to focus more on the half of the skill set that you still need to obtain.

In addition to welding skills, hyperbaric welders need to be able to move with ease underwater, which means taking and passing commercial diving lessons. It usually takes between 2.5 to 6 years to become a certified underwater welder.

During your training, you’ll learn not only commercial diving techniques and how to use them in the context of hyperbaric welding, but complementary skills such as cutting, rigging, fitting, and underwater photography.

The Risks and the Rewards

There is no denying that underwater welding can be a dangerous business. Any time electricity and deep sea diving and pressures are involved, so too is a great deal of risk present.

The slightest slip up could lead to anything from a botched job to electrocution to the bends or other diving-related issues.

That said, the rewards for a successful career as an underwater welder are potentially immense. Divers can often make between $25K and $80K, though six figure salaries for experienced hyperbaric welders is not uncommon.

Moreover, you have the satisfaction of knowing that you’re engaged in work that is constructive, rarified, and a distinct challenge that not everyone can do.

Hyperbaric welding can feel like a blend of engineering excitement, Indiana Jones, and Twenty Thousand Leagues Under the Sea all welded together in a unique aquatic career.

If you already possess a diving or welding skillset or are looking for a fresh challenge with a flush pay scheme for experienced personnel, the potential rewards of underwater welding well exceed the risks.

Dry Versus Wet Welding

The two main types of underwater welding are dry and wet welding.

The first of these demonstrates a misnomer and misconception about underwater welding, which is that it is all done underwater. On the contrary, while much of the work is indeed done while a welder is underwater, since it makes use of many conventional welding techniques as well, it can also be performed in dry conditions.

Dry welding involves making use of a hyperbaric chamber, wherein much of the welding takes place. This is also why hyperbaric welding is another variant of underwater welding.

This enables the welder to work within a dry atmosphere while still beneath the water that contains a mixture of different gases that would not be possible otherwise. This allows the welder to weld in a controlled, reliable setting.

That said, hyperbaric chambers can be expensive, which is why wet welding can be a solid cost-effective alternative. Practitioners make use of a shielded electrical arc that utilizes an attached power supply.

Due to the risks and difficulties it poses, wet welding is less preferred than hyperbaric welding. For one thing, wet welding can lead to quality issues, with the welded joints cooling too quickly as a result of the water causing the heat to dissipate rapidly.

This can lead to the welded metal cracking or the joints becoming defective. For that reason, it is of the utmost importance to make sure that the rate at which the metal cools when welding is watched carefully and highly controlled.

It is practically impossible to achieve the level of care needed for this when welding in the open water.

Welding Techniques

Within that main division of wet versus dry underwater welding, there are several different types of techniques. Just as there is a different task for every job, so too are there different ways to get the job done when faced with a task that requires underwater welding.

Three of the most common hyperbaric welding techniques include:

- Shielded Metal Arc Welding: This is easily the most common type of underwater welding, being used more than 90% of the time, especially when wet welding is involved. It is also known as stick welding, because it involves using cylindrical nodes to create an electrical arc. It can be used for aluminum, stainless steel, and a whole host of other metals, making it one of the most versatile underwater welding techniques.

- Flux-Cored Arc Welding: This technique uses a spool that provides a constant feed, giving welders some vital filler metal, including cast-iron and nickel alloys.

- Friction Welding: This uses – you guessed it – friction to generate the heat necessary for successful hyperbaric welding. It is used for various thermoplastics and metals.

A blend of diving skill and engineering ingenuity, hyperbaric welding brings the magic of metalworking under the sea.

Source: weldingheadquarters.com

More Welding Articles

How Long Does It Take To Learn Welding?