If you’ve always dreamed of combining a love of construction with a fascination with the underwater world a career in underwater welding feels like a perfect fit. The demand for underwater welders is increasing from year to year and the salary is the highest in the industry.

The work is physically demanding, to be sure, and requires someone that can think on their feet – and there’s no shortage of danger anytime you’re talking about welding underwater – but it’s also one of the most rewarding careers you can think of in a bunch of different ways.

Let’s get to it!

Table of Contents

Is Underwater Welding a Good Career?

Underwater welding can be a good career for some individuals, offering unique benefits and challenges. Pros of underwater welding include a good salary, cost-effectiveness, and the opportunity to work in a specialized and vast field.

However, there are also significant cons to consider, such as expensive and hard-to-find equipment, extreme hazards like decompression sickness and electrocution, potential health problems due to prolonged exposure to water, and reduced visibility while working.

Deciding if underwater welding is a good career ultimately depends on an individual’s personal interests, willingness to undergo extensive training, and ability to manage the risks involved.

For those who enjoy working in challenging environments and have a passion for diving, underwater welding can be an exciting and rewarding career choice.

Underwater Welder Salary

The average annual salary of underwater welders ranges from $54,000 to $300,000, making underwater welders the highest paid job in the industry. However, there is an extensive training program that welders must go through before they are approved for underwater welding.

How much do underwater welders make in the Navy?

The average yearly salary of an underwater in the Navy ranges from $40,000 – $100,000. Offshore underwater welders spend most of their time on oil rigs or large marine vessels like Navy ships

How Does Underwater Welding Work?

Underwater welding works through two primary techniques: wet underwater welding and dry underwater welding, also known as hyperbaric welding.

Wet underwater welding is performed directly in the water, without any mechanical barrier separating the welding area from the surrounding water. The most commonly used techniques for wet welding are Shielded Metal Arc Welding (SMAW) and Flux Cored Arc Welding (FCAW). In this method, a waterproof electrode is used, and the electric arc is struck between the electrode and the workpiece, causing the metal to melt and form a weld.

Dry underwater welding, or hyperbaric welding, takes place in a dry environment created by sealing off the welding area with a chamber or habitat. Gas Tungsten Arc Welding (GTAW) is commonly used in this technique, producing high-integrity welds. The welding is performed in a controlled, pressurized environment, reducing the risk of defects and ensuring a higher-quality weld.

In both techniques, safety precautions are crucial. Divers must wear insulated gloves, use appropriate clamps, and ensure the correct polarity and generator size. Additionally, pre-job safety analyses and thorough inspections are conducted to minimize risks and ensure the integrity of the welds.

Underwater Welding 101

What is underwater welding? Well, the fancy way of describing an underwater welder would be someone involved in subaquatic maritime construction and recovery, an individual that fuses metals together at elevated pressures while immersed in different water conditions.

There is obviously a world of difference between welding under the water and welding on land, but a lot of that difference comes down to the equipment that you’ll use and the techniques you’ll have to master as you develop the skills and abilities.

It’s also important to understand that a lot of underwater welding professionals are also called in not to build or to repair equipment that is underwater and cannot be recovered to the surface just yet, but these professionals are also often required to inspect sites, to prepare sites for recovery, and to cut metal and material away rather than join material together to make recovery or repair easier.

UNDERWATER WELDING >> Check out the video below:

There is a varied skill stack that you’ll need to develop as an underwater welder, starting with welding skills and commercial scuba diving skills but then rapidly expanding into inspection skills, underwater photography and videography skills, drafting, and more.

One of the big reasons that underwater welders get paid as well they do is because of the danger that they face every time they dip below the surface, but they also have to be great thinkers as well as great technicians.

You’ll need to troubleshoot problems on-the-fly, you’ll need to be able to develop plans of attack to efficiently operate underwater, and you’ll need to be able to deal with all kinds of challenging conditions that inevitably arise when you’re doing something as technically difficult as welding while surrounded by water.

Don’t let the difficulty of this career put you off, though.

Anyone with dedication, hard work, and a commitment to this field will be able to master these varied skill sets and earn a fantastic living doing something that is as far away from a traditional 9-to-5, punching the clock kind of office job as it gets.

Career Opportunities as an Underwater Welder

Like any other field, you will have an opportunity to specialize in a couple of different areas when you become an underwater welder.

It’s not a bad idea to have an inclination of how you’d like to specialize in this field as you move through your early training and your early certifications. But if you would like to start off as a generalist, getting your feet wet in the field (so to speak) before you choose how you’d like to specialize that’s perfectly fine, too.

There are a bunch of different ways that you can differentiate yourself in this industry, but the overwhelming majority of underwater welders are going to separate themselves into three different categories. We highlight those below.

But before we do, please remember that you can certainly get certifications and experience in all three of these areas if you are interested. There’s no rule that says you have to specialize in just one area or another.

In fact, some of the most accomplished (and well-paid) underwater welders have a bit of experience in all of these areas while really laser focusing on just one or two.

Related reading: Do Welders Make Good Money? – Highest Paying Welding Jobs

Wet Underwater Welding

Wet underwater welding is an approach that uses a shielded metal arc to handle the actual welding process itself, most often leveraging a waterproof electrode (though sometimes flux cored arc welding and friction welding approaches are taken advantage of).

What underwater welding is usually practiced when you are dealing with low carbon steel materials, particularly when you are diving at significantly deeper depths than you might have been in a more traditional environment. Hydrogen caused cracking can occur otherwise, and that’s something that you’ll want to avoid when you are looking to join things together (for obvious reasons).

I have recently written an article in which I describe wet underwater welding in more detail, read this article here

The number one way that what underwater welding differentiates itself from dry underwater welding is that there is no dedicated chamber to separate the actual welding process from the water that you are in.

Every time you generate an arc the electrode that you are using builds its own gaseous bubble inside of the water that shields everything from corrosive gases and the water itself, a bubble generated by direct current feeding the electrode (just because it’s so much safer).

You’ll almost exclusively have to use Shielded Metal Arc (SMAW) welding approaches that are commonly referred to as stick welding, though flux cored and friction welding options are available as well like we highlighted a moment ago.

This kind of welding is usually used as a last resort because of the higher danger levels involved, but also because the water cools down the material very quickly which can lead to cracks and compromising of your welding job.

Related reading: 7 Steps for Avoiding Electric Shock When Welding Underwater

Dry Underwater Welding

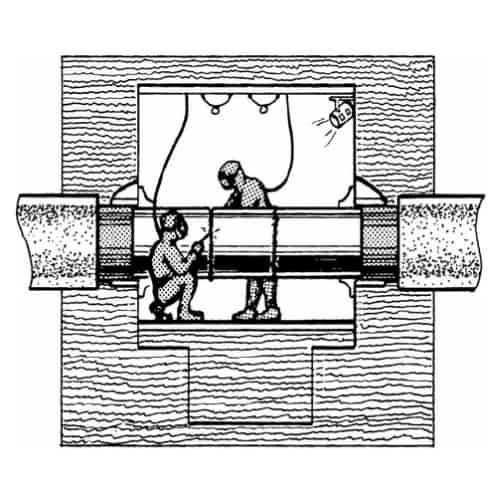

Dry underwater welding, on the other hand, is usually conducted inside of a hyperbaric chamber that not only shields the welder from the water around but also shields the area that you are working with from the water around you as well.

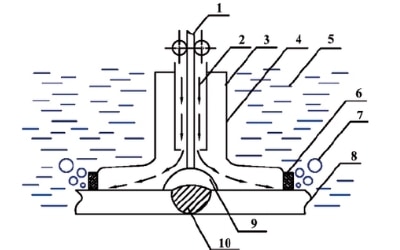

This process is created by building some sort of seal around the structure or equipment that you are working on. From there, hoses are connected to that seal that pumps out water and then replaces it with a mixture of different gases (oxygen and helium) that allow for more traditional “landlocked” welding to take place even though you are beneath the water.

I have recently written an article in which I describe dry underwater welding (Pressure welding, Habit welding, Dry chamber, and Dry Spot Welding) in more detail, read this article here

The hyperbaric chamber is then pressurized to protect the welder which will usually be at lower depths for extended amounts of time, giving them plenty of opportunity to work at their own pace and with a clean and dry surface that wouldn’t have been possible with wet welding.

Four different kinds of dry welding approaches are commonly leveraged, including:

- Pressure welding

- Habit welding

- Dry chamber welding

- Dry spot welding

Pressure welding occurs inside of pressurized vessels with a single atmospheric unit of pressure.

Habit welding happens inside small room sized chambers that they can move around it.

Dry chamber welding usually only covers the head and shoulders of the diver.

Dry spot welding usually involves working inside of a balloon size and transparent “habitat” that really only covers the welding equipment itself.

Deep Underwater Welding

There are also some underwater welders that specialize in deep underwater welding, and this is definitely an exciting field to get into where new research is happening on a regular basis – but it’s also one of the most dangerous areas of the underwater welding world to get into.

These kinds of underwater welding situations are almost always dry water welding situations, especially since the amount of pressure underwater combined with the rapid cooling of the welds themselves in a wet environment would destroy the work almost straight away.

The U.S. Navy is really pioneering work in the deep underwater world of welding, and if you’re serious about diving down to depths of 1000 m (or even deeper) to do work on shipwrecks, accident sites, underwater laboratories, and the like you may want to consider enlisting and taking that approach to get your education and training. This is something that we will cover in just a little bit.

Skills You’ll Need to Develop as an Underwater Welder

Underwater welders are going to have to develop a diverse skill set and stack of abilities that they can use every time they slip beneath the surface of the water, especially since they are (for the most part) going to be operating all on their own – even when they are working as part of a dive team.

As we have highlighted earlier, there’s a lot of risks and a lot of danger to being an underwater welding professional.

Drowning, explosions, electrical shocks, serious injury and death because of decompression changes and decompression sickness, and hypothermia are just some of the potential risks your face every time you put on your diving gear and head down to a worksite.

Combine that with all of the traditional risks associated with construction projects, the fact that you are working with some pretty volatile materials that aren’t traditionally used under the water, to begin with, and everything else that can go sideways on a dive you have to be so careful and so skillful if you’re going to get into this industry.

Here are just some of the skills you’ll need to develop as an underwater developer to have real success in this business.

Welding Skills

Welding skills are obviously going to be paramount when your entire job relies on your ability to knock these types of projects out successfully while you are underwater.

Welding is a technically demanding skill to master and a skill that you are going to be developing and improving on every single day of your career.

There are a variety of different fuels, variety of different approaches to welding, and a variety of different tools and technologies you can use – and the job site and the environment is almost always going to dictate how you have to go about approaching the welds you are looking to create.

You’ll have to master oxy fuel welding for sure, but it’s not a bad idea to develop proficiencies in more traditional “land-based” welding areas as well. You want to practice as much as you can – above water and below – since this is going to be your bread and butter skill in the field.

Diving Skills

Diving skills are just as important as your welding skills, and maybe even more important as the environment around you that you are swimming in can become deadly in an instant if you don’t know exactly what you are doing.

There’s a world of difference between the scuba skills you’ll need as a welding diver compared to those you might be about on vacation or on a honeymoon. Not only are you going to need to get your underwater commercial diver certification, but it’s a good idea to get your underwater rigger certificate, deepwater training, and to get checked out on all kinds of scuba technology that you might use in your field.

Like any other skill, diving skills need to be practiced on a regular basis for you to remain proficient.

It’s critically important that you dive as often as you can even when you aren’t working on a project to keep your skills current. You’ll also want to look for opportunities to get more in depth training from experts in the field, especially if your future employer provides these kinds of trainings as part of your employment contract.

The number one thing as an underwater welder is to learn to become completely comfortable underwater, to the point where slipping beneath the surface is no different than slipping out of bed.

You need to trust your gear and equipment, you’ll need to trust your skills and abilities, and you’ll need to trust that you will know how to troubleshoot any of the accidents or emergencies that can go wrong when you are down below – and that’s only going to come with time, experience, training, and wisdom.

Underwater Cutting Skills

Your ability to cut material away underwater is almost as important as your welding abilities, which is why you’ll need to master underwater cutting technologies like oxy fuel cutting, abrasive jet cutting, and the use of mechanical cutting tools that you might need underwater.

You’ll need to know how to safely cut things away, how to plan cuts so that everything falls exactly where you wanted to (away from potentially dangerous areas), and how to diagnose these situations when you are hands on the structure or equipment you are working on – changing the plan on the fly (communicating to your team) as necessary.

The skillful ability to remove material and to cut away obstructions is a huge piece of the puzzle. The right cuts make your job as an underwater welder a whole lot easier as well as a whole lot safer, and it’s critical that you don’t look at this as a traditional demolition job but look at it instead the way that a surgeon does.

Skillful cuts that are very deliberate and very intentional, designed to cut as little as possible but enough to get the job done, will go a long way towards not only improving your results boosting your reputation (and your earning potential) as a professional.

Fitting and Rigging Skills

Fitting and rigging skills go hand-in-hand with your welding abilities, especially since the second that you slip underwater and start to work on these kinds of projects you’ll usually be a bit of a one-man Swiss Army knife – knocking out whatever needs to be tackled on that particular project since you can’t swarm it with dozens and dozens of divers all at once.

These skill sets added to your skill stack make you much more attractive higher, give you a lot more earning potential, and can help you lock up the kinds of career opportunities that might not have been available if you didn’t focus on developing the skills early on in your career.

Inspection and Non-Destructive Testing Skills

There are plenty of professional inspectors and testers that are underwater certified, but any true professional underwater welder is going to want to have plenty of know-how, plenty of training, and plenty of skill in the area of inspecting and diagnosing the worksite they are going to be working on.

You’ll want to know enough to be able to inspect a site, create a plan of attack that keeps you and your team safe, and understand how to test things (using visual, ultrasonic, radiography, or magnetic particle solutions) so that there are as few surprises when you get to work as possible.

Again, this is kind of a specialist skill that not every underwater diver is going to accumulate – but it’s one that can boost your earning potential and your peace of mind and confidence tackling projects under the surface of the water.

Drafting Skills

Drafting skills (at the very least the ability to read plans that have been drafted quickly and efficiently) are essential skills that you’ll want to learn and then master as an underwater welder.

The last thing you want to find yourself doing beneath the surface of the water is “freelancing”, and you certainly don’t want to work with a team of divers and welders that are running off script because they don’t fully understand drafting, either.

This is a skill that you’ll learn every single day on the job as well as a skill that will be drilled into you during your foundational education. Continue to master and develop it throughout your career and you’ll be good to go.

Underwater Photography and Videography Skills

Underwater photography and videography take advantage of some pretty specialized technology, the technology you want to become intimately familiar with so that you can be totally comfortable snapping photos and quick videos of the worksite that you will be on.

You don’t necessarily have to become a world-class artist when it comes to photography and videography, but you’ll definitely need to understand how to maximize lighting, how to hit the right angles, and how to physically manipulate and use the gear and the equipment designed to work underwater for sure.

The underwater photos and videos you collect almost exclusively be used in the planning of how to best approach each welding project you deal with. The more attention to detail these photos and videos focus on the safer you can feel tackling a project.

How Do I Get Started?

As much as we would like to tell you that there is a cut and dry pathway to becoming an underwater welder, the truth is there are a bunch of different avenues of approach you can take – both in the civilian and material worlds.

We can tell you that the overwhelming majority of underwater divers are either going to go to a specialized trade school that focuses exclusively on underwater welding or are going to join the U.S. Navy and get training in this specialty as part of their enlistment contract.

The younger you start in this career field the more longevity you are going to have, as there aren’t too terribly many underwater welders that are working day in and day out beneath the surface once they hit their late 40s or early 50s.

The job is just so physically demanding that you’re not likely to see a bunch of gray-haired divers working on rigs.

That being said, you don’t necessarily have to be a spring chicken fresh out of high school to get into the world of underwater welding, either. Plenty of people start off in other trades – or as traditional welders – that move over to underwater welding later in life (their mid to late 20s and early 30s) and still have a lot of time in their career to make quite a bit of money.

Let’s get into how you should get started in this career.

Finding the Right Underwater Welding School

If you are going to go the civilian route you’re going to want to make sure that you find an underwater welding school that specializes in this trade, a school that has a great reputation for teaching and training underwater welders and a school that is recognized as an industry leader – one that can make you a safe underwater welder as well as a competent and skilled one, too.

Almost all underwater welding schools are going to require that you have a high school diploma or a GED equivalent, that you have some surface welding certifications and experience, and that you are either commercial diving certified or are going through the training to get that commercial diving certificate, and that you are eager to learn these skills forward.

Once you square those things away you’ll want to important things to focus on these key details to find the right underwater welding school to sign up for!

Location

The location of the underwater welding school that you choose is obviously a huge piece of the puzzle.

Not only should this diving school be located next to a gigantic body of water so that you can get regular hands-on training (almost all of them are located on the coast so that you can get out in the ocean to train), but it also should be in an area that you feel comfortable moving to and living in – especially if there are a lot of organizations in the area that hire directly from that school.

A lot of great underwater welding schools are set up in areas that have a lot of underwater construction going on, with many local organizations hiring students straight from these schools. You’ll want to consider this before you get started, as you could spend years – if not decades – training and then living in an area after you graduate.

Related reading: Offshore Underwater Welding Jobs: Description and Salary Details

Program Duration

On average, underwater welding courses are going to last about 25 to 26 weeks, though some of the more specialized courses stretch out to 88 weeks or even longer.

There are some schools that promise that they can get you “in and out” inside of 6 to 12 weeks, but (for obvious reasons) these kind of “quick fix” schools should probably be avoided by those that are serious about really building a career in this industry.

The last thing you want to do is shortchange your education or your earning opportunities, and we can tell you with a lot of certainties that the odds of you getting a complete education you need – especially in specialist areas – in the world of underwater welding in just 12 weeks is slim to none.

Reputation

Not only should you choose an underwater welding school that has a fantastic reputation for safety and education in this field, but you should also choose a school that has a fantastic reputation for helping their students build their careers upon graduation.

The best schools in this industry are always going to give you the foundational skills and abilities you need to master the world of underwater welding – but they are also going to help you find great paying jobs with good companies in the industry, too.

It might not be a bad idea to call your ideal future employer (or a handful of them) to see where they hire the majority of their new underwater welders. That’ll give you a good idea of at least a handful of the schools that you want to focus on especially if you know that graduates are getting jobs – great jobs – right after graduation.

How Much Does it Cost to Become an Underwater Welder?

The tuition for training as an underwater welder isn’t going to be anywhere near as expensive as a traditional college or university, but it isn’t going to be free, either (unless you sign up for the Navy, of course).

How much does it cost to become an underwater welder? On average, underwater welding training will run you about $15,000 “all-in” – though sometimes it’s a bit more expensive than that, sometimes hovering around $18,000 or even $20,000.

You’ll usually also have to pay or your equipment, any of the books and training materials that aren’t provided by the school, traveling, and your living expenses if there isn’t a campus. That’s definitely something you’ll want to factor into your decision.

There are some programs out there that offer tuition assistance and grants, though, that you’ll want to look into as well. Some programs even offer scholarships, and there are even a number of employers out there that will pay for some or all of your education as an underwater welder as part of your employment package.

Joining the Navy

Of course, you could always go the military route to learn the skills and abilities necessary to get into the world of underwater welding by signing up for the U.S. Navy.

You’ll have to make (at minimum) a four-year commitment to get into this field as part of your naval enlistment, but you’ll no longer have to pay to get the job training you need – but will instead be getting paid by the U.S. Navy to learn the skills you use throughout your career.

It also doesn’t hurt that this training is some of the best in the world, giving you an opportunity to take advantage of some of the most impressive technological advancements and equipment designed for the world of underwater welding while working on a diverse array of projects and construction sites.

Many underwater welders working for the Navy will also get to see the world, will get a host of veteran benefits when they leave the military, and will almost always have the pick of the litter when it comes time to find a job in this field after their enlistment ends.

This may or may not be an approach that you are interested in, but it’s definitely one that you want to seriously consider for sure.

Frequently Asked Questions

Here are a few common questions people often have about underwater welding:

Are Underwater Welders in High Demand?

Yes, underwater welders are in high demand. There is a growing demand for underwater welders around the world, particularly in view of the need to maintain and repair damage to oil platforms and other massive marine infrastructure.

Do Underwater Welders Travel a Lot?

Yes, underwater welders usually travel a lot, from one drilling platform to the next. however, due to your intensive schedule, underwater welders usually return inland after a month at sea.

Their work schedule rarely slackens: It’s not unusual to work 80 or more hours in a single week.

References